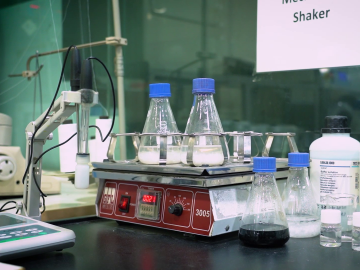

Laboratory (LAB)

Accurate shade matching, testing and approvals with standardized methods to support fast sampling and reliable bulk references.

- Color matching & shade approval

- Performance & compliance testing

- Stable bulk reference control

Unifill Composite Dyeing Mills Ltd. is committed to producing high-quality woven and knit fabrics that meet customer, buyer, and regulatory requirements. We ensure compliance through Right-First-Time production, on-time delivery, and continual improvement—reducing defects, empowering employees through training, and promoting sustainability by using resources responsibly. This policy is communicated to all employees, reviewed annually, and forms the basis for measurable quality objectives.

Our integrated Laboratory, Quality Assurance and Quality Control system ensures Right-First-Time production, compliance readiness and consistent buyer-approved quality.

Accurate shade matching, testing and approvals with standardized methods to support fast sampling and reliable bulk references.

SOP-driven monitoring across pretreatment, dyeing, printing and finishing—ensuring system compliance and continual improvement.

Stage-wise inspections from incoming to final shipment—only compliant, defect-free fabrics are released.

Our Quality Management System is guided by a clear vision and mission that define our commitment to excellence, compliance, and continual improvement.

To be a globally recognized and sustainable textile manufacturer by delivering innovative, eco-friendly, and high-quality woven and knit fabrics that build long-term trust with customers and create value for stakeholders.

To consistently deliver Right-First-Time quality fabrics through robust QMS, skilled people, controlled processes, and strict compliance with ISO and buyer standards—ensuring on-time delivery and customer satisfaction.

Our quality commitment is embedded in every stage—from pretreatment to final inspection—supported by training, audits, CAPA, and data-driven continual improvement.

Measurable goals aligned with ISO 9001:2015 and buyer compliance expectations. Considering baseline year 2024.

Improve RFT across Dyeing & Printing to ≥ 96% by 2028.

Maintain ≥ 98% pass rate in final inspection by 2028.

Reduce re-dye/rework to ≤ 4% by 2028; strengthen defect calibration.

Reduce customer complaints to ≤ 1% and improve OTD to ≥ 95% by 2028.

Achieve ISO 9001:2015 certification by 2027 and ensure 100% ERP traceability by 2028.

Ensure 100% QC/QA/Production staff trained annually on SOPs, buyer standards & defect calibration.