Our dyeing operations are supported by advanced machinery, automated process control,

and experienced technical teams to ensure consistent color performance across batches.

Each stage is monitored through defined quality checkpoints, enabling reliable shade

matching, reduced rework, and improved right-first-time performance.

We strictly follow international buyer requirements, chemical compliance protocols,

and environmentally responsible practices, integrating ETP-linked processing and

full batch traceability from greige to finished fabric.

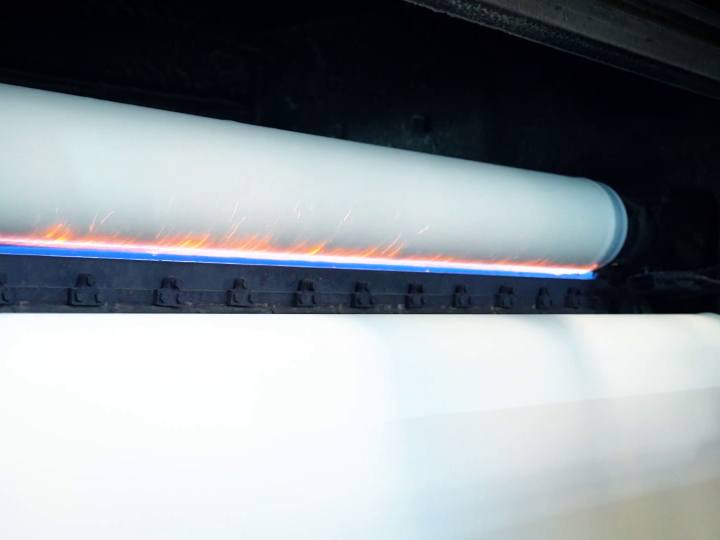

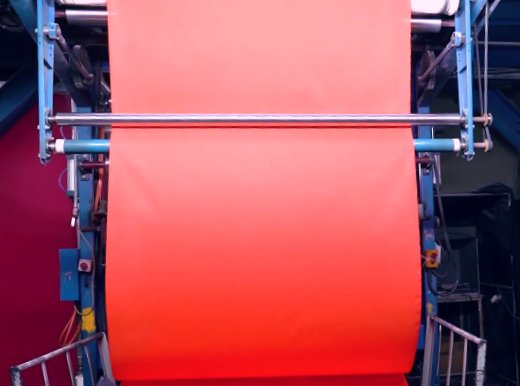

Continious dyeing with controlled recipe execution for uniform shades and repeat orders.

Stable pretreatment + dyeing base quality to support all-over printing requirements.

Controlled chemical use, documentation readiness, and environmental stewardship.

A structured workflow that ensures consistency, quality, and traceability at every stage.

Versatile fabric portfolio supporting solid dyeing and pigment printing.

Built-in checks reduce rework and ensure batch-to-batch stability.

Controlled parameters ensure repeatability and stable production performance.

Integrated systems ensure responsible production and regulatory compliance.

Our dyeing operations are designed around buyer requirements—accurate shade matching, stable process control, compliance-ready chemical management and dependable repeat-order performance. We support buyers with transparent communication, technical guidance and production reliability from lab approval to bulk delivery.

Key standards and programs supporting compliance-driven dyeing operations.

OEKO-TEX

OEKO-TEX GRS

GRS GOTS

GOTS OCS

OCS RCS

RCS BCI

BCI