Smart Production & Operational Excellence: We ensure seamless fabric processing with advanced machinery, skilled teams, and strict quality controls at every stage to deliver consistency, reliability, and superior product standards.

Compliance & Sustainability Commitment: Unifill operates with full adherence to global compliance frameworks, safe chemical management, environmental responsibility, and ethical workplace standards to meet leading brand requirements.

Innovation-Driven Continuous Improvement: Through modern technology, optimized workflows, and a culture of innovation, we continuously enhance efficiency, reduce waste, and improve product performance for our customers.

At Unifill Composite Dyeing Mills Ltd. (UCDML), our success is built on the expertise and dedication of our people. As a flagship concern of Unifill Group, we lead the industry in sustainable dyeing, printing, and finishing by combining advanced technology with a skilled workforce. We remain dedicated to the principle that our business thrives when our people do.

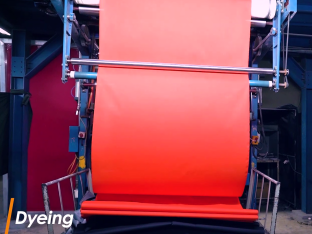

Modern and Eco-friendly dyeing facilities with precise process control ensure uniform shade quality, color fastness, and high production efficiency for woven and knit fabrics.

Modern All Over Printing (AOP) technology delivers sharp designs, consistent color reproduction, and scalable production to meet diverse global brand requirements.

Comprehensive in-house quality control and laboratory testing ensure every batch meets international standards for performance, durability and compliance.

Comprehensive sustainability practices and responsible resource management ensure environmentally compliant, safe & efficient production across all operations

Higg Index

SLCP Verified

ISO 14001:2015

OEKO-TEX Standard 100

SEDEX

Better Cotton Initiative

GRS Certified

GOTS Certified

RCS Certified

OCS Certified

ZDHC

ZDHC Wastewater

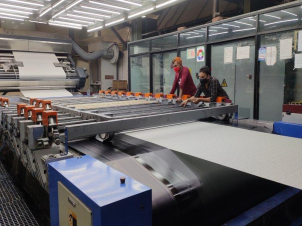

Our operations follow a streamlined, technology-driven workflow—from material inspection to dyeing, printing, finishing, and final quality checks. With skilled teams and modern machinery, we ensure consistent quality, efficiency, and sustainable production at every stage.

A well-planned industrial facility designed for efficient, safe and sustainable textile production.

A dedicated space showcasing fabric samples, designs and product developments for buyers.

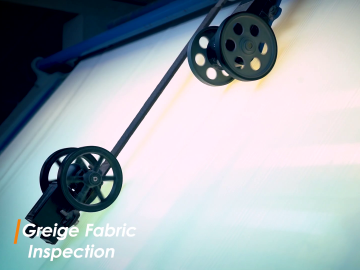

Thorough inspection of greige fabric to ensure quality compliance before processing begins.

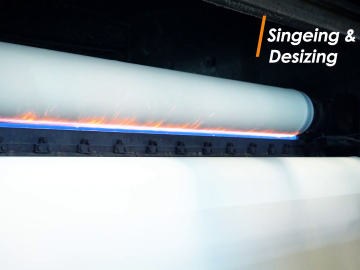

Removes surface fibers and impurities to ensure smooth, clean fabric for further processing.

Pre-treatment prepares fabric for dyeing and printing through controlled bleaching and mercerizing processes.

High-capacity dyeing machines delivering uniform shades with strict process control.

High-speed rotary printing delivers uniform patterns and vibrant colors with consistent quality.

Advanced flatbed printing lines ensuring precise designs and consistent print quality.

The stenter machine is used for fabric drying, heat setting, width control and dimensional stability, ensuring uniform quality.

The finishing process enhances the fabric’s final appearance and performance by improving softness, smoothness, dimensional stability, and handle.

Fabric inspection is carried out at every stage to ensure color accuracy, surface quality and defect-free finishing before delivery.

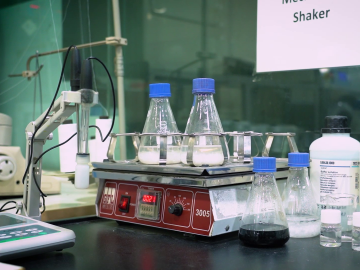

Our in-house laboratory performs chemical, color fastness and performance tests to ensure compliance.

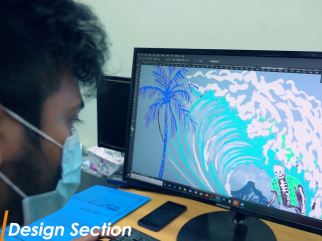

The design team develops creative print and pattern concepts using digital tools, aligned with buyer trends and customer requirements.

Wastewater (150 m3/hr) is treated through a modern ETP system to meet environmental regulations.

A visual presentation of diverse garment samples reflecting our expertise in fabric processing, color development, printing and finishing.

At Unifill we aspire to be a globally leading trusted and sustainable fabric manufacturer that offers one-stop solution to Dyeing and Printing of fabrics ensuring premium quality through innovation, sustainable and responsible production for better future.

Each concern operates with a clear focus, collectively forming a vertically integrated and compliance-driven manufacturing ecosystem.

Woven garment unit with in-house embroidery, print and washing facilities for value-added apparel production.

Sweater manufacturing unit with integrated embroidery, printing and washing capabilities.

Dedicated garment washing unit with high-end automated and environmentally responsible technologies.

Fully equipped woven garment manufacturing unit, sister concern of AGDL.

Fully equipped sweater manufacturing unit, sister concern of AKL.

High-capacity sweater manufacturing unit aligned with global quality and compliance standards.

Modern sweater production facility with strong design and finishing capabilities.

Sweater manufacturing unit operating with full in-house production and compliance systems.

Fully equipped sweater manufacturing unit supporting global brands under Aman Knittings Ltd.