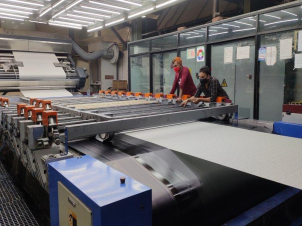

Our printing division delivers high-quality fabric printing with strong shade clarity,

sharp design definition and repeat-order consistency. We operate both Rotary and Flatbed

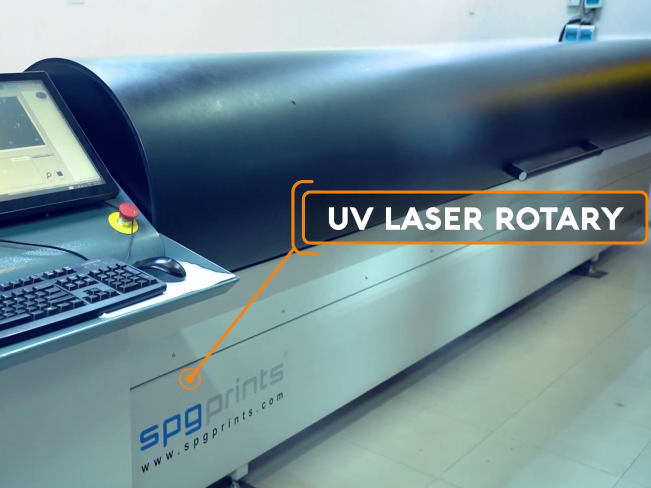

printing facilities, supported by an in-house Engraving & Screen Development section for

faster sampling, accurate execution and stable bulk production.

From design approval to final inspection, each step follows defined quality checkpoints,

compliance-ready chemical handling and controlled process parameters—ensuring reliable

delivery for woven and knit Print capability.

High-speed production printing with stable color output and repeat-order reliability.

Precision prints for detailed designs with controlled paste, pressure and registration.

Engraving & screen development support for faster sampling and accurate bulk execution.

A controlled workflow ensuring design accuracy, quality stability and traceability.

Both printing platforms to support multiple design types and production needs.

In-house preparation to speed up sampling and improve execution accuracy.

Checks are built-in to reduce rework and ensure batch-to-batch stability.

Responsible chemical handling with documentation and operational discipline.

Our printing focus is centered on design accuracy, stable bulk repeatability, compliance-ready chemical management and dependable on-time delivery. From sampling support to bulk production, we maintain clear communication, controlled process discipline and quality assurance for both rotary and flatbed printing, including knit print capability as per program requirement.